How to Achieve Long-Lasting Prints with DTF Transfers

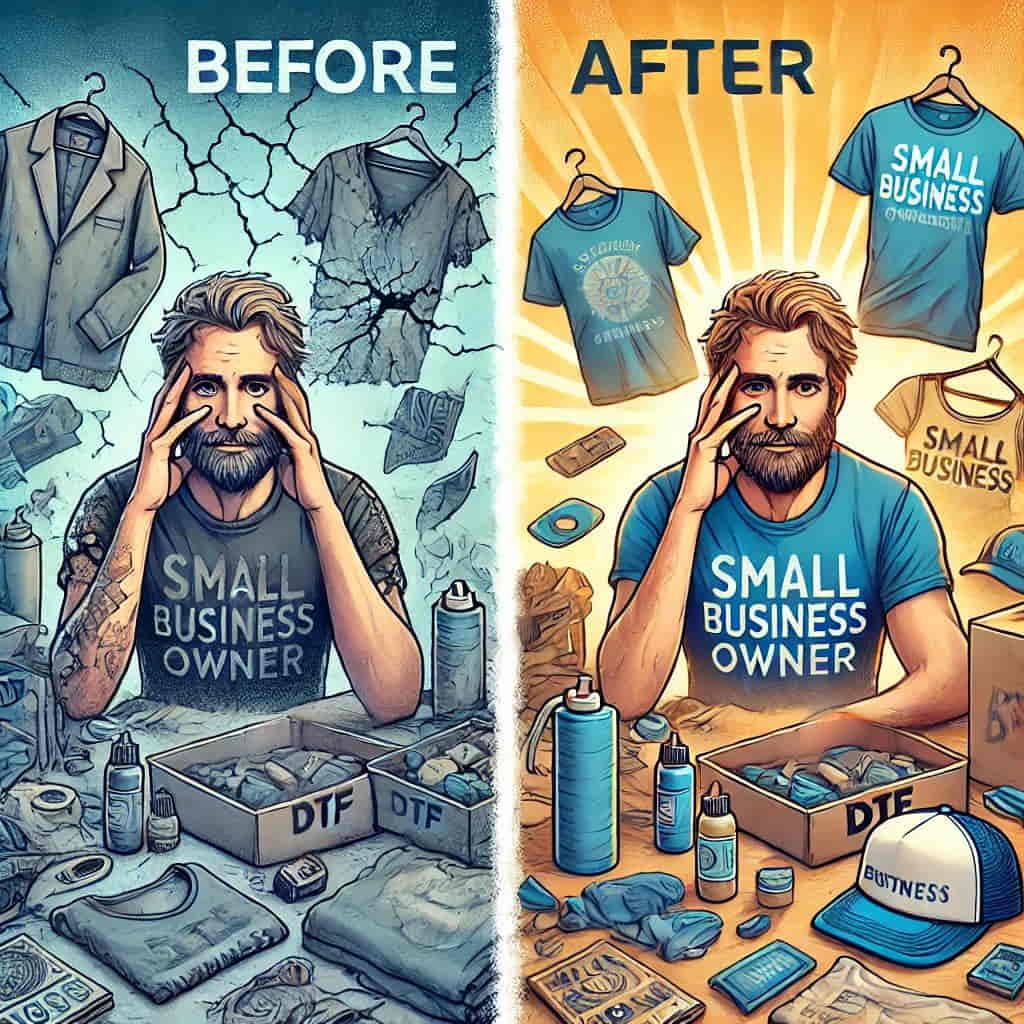

You’ve just received a bulk order of t-shirts for a corporate event. They look perfect – bright, crisp logos splashed across soft, high-quality fabric. But a few washes later, those vibrant prints start to fade, crack, or peel. That’s the last thing you want for your business, right? Enter bulk DTF Transfers. If you’re aiming for long-lasting, durable prints, understanding how DTF transfers work – and how to ensure they stand the test of time – can be a game-changer for your business.

So, let’s dive into the world of bulk DTF Transfers and explore how you can achieve long-lasting, eye-catching prints that leave a lasting impression (literally!).

What Exactly Are DTF Transfers?

First off, if you’re new to the world of printing, you might be wondering what makes DTF (Direct-to-Film) transfers special. Unlike traditional screen printing or heat transfer methods, DTF transfers involve printing your design directly onto a special film, applying a powder adhesive, and then heat pressing it onto the fabric.

The result? A durable print that sticks to just about any fabric type – cotton, polyester, blends – you name it. With bulk DTF transfers, businesses can now produce large orders efficiently while ensuring every print is consistently vibrant, detailed, and long-lasting.

Now, the key word here is “long-lasting.” No one wants to deliver t-shirts that look fantastic on day one and shabby by day 10. So, how do you ensure your DTF prints go the distance?

The Science of Durability: What Makes a Print Last?

To understand how to get those prints to endure, you need to grasp what causes them to fail. Common issues with prints include fading, cracking, and peeling, and these are often due to poor adhesion, low-quality ink, or a subpar transfer process.

Here’s a quick look at the core factors that can make or break your bulk DTF transfer prints:

- Quality of the Transfer Film: The foundation of every great print starts with high-quality materials. Using a reputable transfer film that’s designed for DTF printing is crucial. Cheaper films can result in weak adhesion, leading to prints that crack or peel quickly. Always go for premium options when ordering in bulk.

- Ink and Powder Adhesive: Not all inks are created equal. DTF requires specialized pigment inks that bond well with the powder adhesive applied to the transfer film. The adhesive powder plays a key role in sticking the design to the fabric. If you’re skimping on ink or adhesive quality, you might as well be throwing money down the drain.

- Heat and Pressure: For the transfer to bond properly, the heat press needs to be set at the right temperature and pressure for the correct amount of time. Get this wrong, and you could end up with prints that don’t fully adhere, or worse – melted fabric.

So, what’s the takeaway? The quality of your bulk DTF transfers is directly tied to the quality of materials you use and the precision of your transfer process. When done right, the result is a print that won’t flinch at a spin in the washing machine or a day under the sun.

Pro Tips for Achieving Long-Lasting Prints

Now that we’ve covered the basics of DTF transfers, let’s get to the good stuff. What steps can you take to ensure those prints last longer than your favorite pair of sneakers?

1. Choose the Right Fabrics

While DTF transfers can adhere to a variety of fabrics, some yield better results than others. Alongside the tried-and-true options like 100% cotton and polyester, you should also consider poly-cotton blends or fabrics like rayon. These blends offer flexibility and durability for bulk DTF transfers, allowing the ink to bond securely without compromising on the softness or breathability of the fabric.

2. Pre-Treat the Fabric

Even though DTF transfers don’t require pre-treatment like direct-to-garment (DTG) printing, it’s never a bad idea to prep the fabric. A light wash before applying the transfer helps remove any residues or oils that might interfere with adhesion. You could also consider using a fabric softener for certain materials. This extra step can help smooth the fabric surface and improve adhesion, particularly with more textured fabrics.

3. Optimize Heat and Pressure Settings

We mentioned earlier how crucial heat and pressure are in the transfer process, but it’s worth repeating. Too little heat, and the adhesive won’t activate properly. Too much heat, and you risk damaging the fabric or ink. Always follow the recommended temperature range (usually between 300-320°F) and adjust the pressure to ensure the entire surface is evenly pressed.

4. Allow Time for Cooling

Once the transfer is complete, resist the urge to peel off the film immediately. Allow it to cool down first. This helps the adhesive fully bond with the fabric, making for a stronger, longer-lasting print. Rushing this step can lead to premature peeling.

5. Post-Press for Extra Durability

Some professionals add a second press after removing the transfer film. This is done by placing a protective sheet (such as parchment paper or a silicone sheet) over the design and pressing it again for a few seconds. This helps seal the design further and improves its durability – like adding a protective topcoat to a fresh manicure.

6. Caring for the Finished Product

Once the prints are on the garments, proper care goes a long way in ensuring they last. Advise your customers to wash the items inside-out, use cold water, and avoid harsh detergents. Skip the tumble dry and opt for air drying whenever possible – a simple step that can add months (or even years) to the lifespan of a printed garment.

Common DTF Printing Issues and Troubleshooting

Even with the best practices, sometimes things don’t go as planned. Here are a few common issues with DTF printing and how to troubleshoot them:

- Peeling Prints: This often happens when the heat press doesn’t apply even pressure across the transfer. Ensure your heat press plate is level and apply consistent pressure.

- Cracking Designs: Cracking typically occurs when the transfer is exposed to too much heat or the fabric is over-stretched. Adjust your heat settings and use the right fabric types to prevent this.

- Uneven Adhesion: This can occur if the powder adhesive isn’t applied evenly or if the transfer film is of low quality. Always make sure the powder coats the entire design and avoid using low-quality materials.

Cost Analysis: The Value of Bulk DTF Transfers

One of the main selling points of DTF transfers is their cost-effectiveness, especially when ordered in bulk. The ability to print complex designs without the need for multiple screens (as in screen printing) or lengthy pre-treatment processes (like DTG) reduces both time and cost. For businesses fulfilling bulk orders, this translates into lower production costs and faster turnaround times – without compromising quality. Bulk DTF transfers also allow for lower minimum order quantities, making them a flexible option for businesses of all sizes.

Conclusion: Durability is Key

At the end of the day, no business wants to deal with unhappy customers returning faded or cracked prints. By investing in high-quality bulk DTF transfers and following best practices, you can ensure that your prints stay vibrant, detailed, and durable for the long haul. Whether you’re producing branded apparel, promotional items, or corporate uniforms, DTF transfers provide a reliable solution that meets the demands of the B2B market.

After all, who doesn’t love a product that looks good and lasts longer than expected?

So, next time you’re planning that big order, consider bulk DTF transfers – your prints (and your bottom line) will thank you.